KM Gantry CNC Series

KM Gantry CNC Series

KA coaxial optical CNC series

KA coaxial optical CNC series

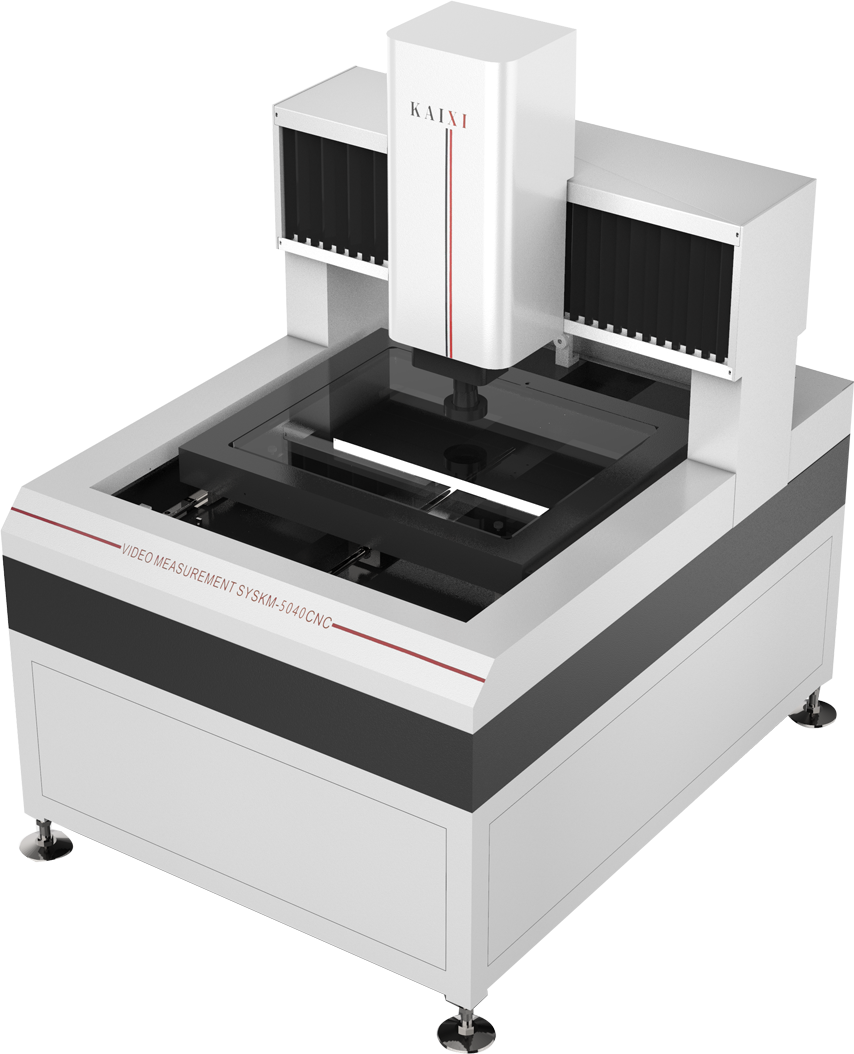

KC Automatic CNC Series

KC Automatic CNC Series

KGF high precision CNC imager

KGF high precision CNC imager

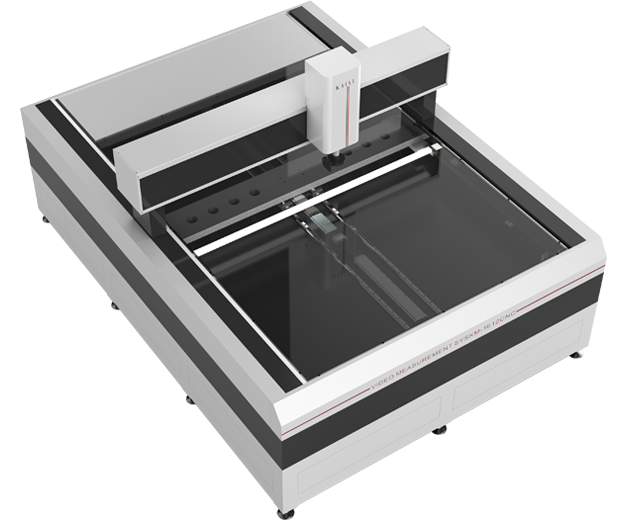

KF high precision gantry system

KF high precision gantry system

KG series automatic video measuring instrument

KG series automatic video measuring instrument

KS series Manual measuring instrument

KS series Manual measuring instrument

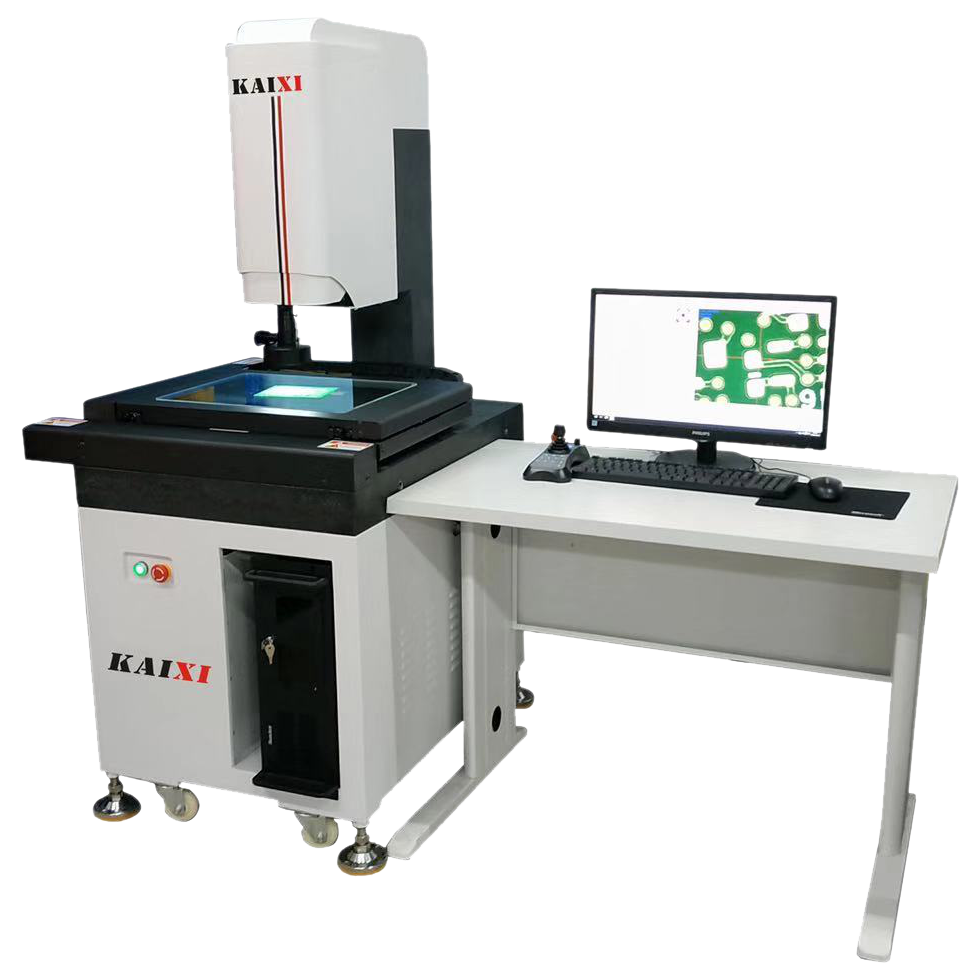

KX series semi-automatic measuring instrument

KX series semi-automatic measuring instrument

Precise transmission equipment design for fast movement.;The columns and base are made of high-precision granite structure, which is stable and reliable.

| ◆ Precise transmission equipment design for fast movement. |

| ◆ The columns and base are made of high-precision granite structure, which is stable and reliable. |

| ◆ Equipped with KX-E multifunctional measurement software to meet different measurement needs. |

| ◆ DXF files can be imported for quick detection. |

| ◆ Measured data can be exported to Word, Excel, AutoCAD, PDF with graphical report output function, easily output test results |

| ◆ Three-axis precision cross roller guides ensure machine accuracy and service life. |

| ◆ Contour measurement function with and without reference |

| ◆ High-definition lens and high-resolution digital CCD to achieve high-definition measurement of products. |

| ◆ The industry's advanced card-mount lens makes it easy to switch the magnification. |

| machine type | KE manual series imager (with probe) | |

| Dimensions(LWH)(mm) | 980*750*950 1080*850*950 1100*950*950 1200*1050*950 | |

| Measuring range(LWH)(mm) | 200*100*200 300*200*200 400*300*200 500*400*200 | |

| Weight(kg) | 230 270 310 410 | |

| Load-bearing(kg) | 30 40 50 60 | |

| X and Y axis measurement accuracy(μm) | 3.0+L/200 | |

| Objective lens working distance(mm) | 90 | |

| system platform | Win 7/10 64 bit operating system (requires resolution 1600*900) | |

| power supply | 220V/50Hz/5A | |

| working environment | Temperature 20 ± 2 ℃, temperature change ≦ 2 ℃ / hr | |

| Magnification | Optical magnification: 0.7-4.5X; image magnification: 44.96-258.63X | |

| Contour light system | LED cold light source, 256-level brightness programmable | |

| Surface light source system | Three-ring LED cold light source, 256-level brightness programmable | |

| Lens | 0.7-4.5X manual fixed zoom | |

| CCD | 1.3 megapixel color digital industrial camera (Haikang) | |

| Operation method | Manuel | |

| Lead Rail | X and Y axis precision cross roller guide Z axis Taiwan "Shangyin" linear guide | |

| Toothless polished rod | Imported toothless screw drive | |

| Probe system | British "RENISHAW" MCP stylus + stylus (1mm, 2mm each) | |

| Data control | Independent research and development program control data source set program control | |

| Grating | 0.001mm | Changchun Optical Machinery Institute |

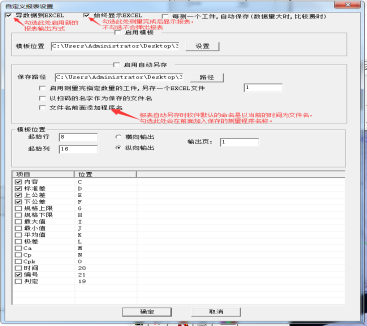

| Measurement software | KX-E | |

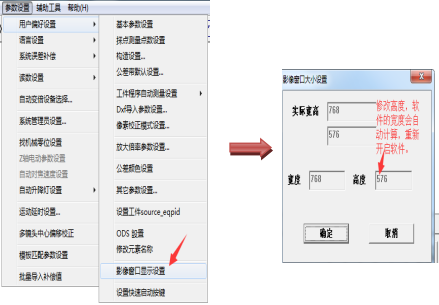

| 1 | Support custom modification of image window size, image window can reach 800 * 1066 resolution can reach 1920 * 1080 | |

| 2 | Support light source control: brightness, partition, full zone, and has perfect light source rotation and recording function | |

| 3 | Support overall image focus, partial focus, high-precision focus measurement height | |

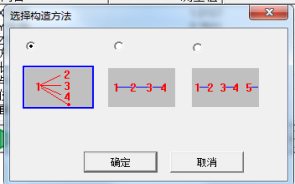

| 4 | Support automatic contour scanning, reverse scanning function and construct points, arcs, circles, straight lines directly in the software | |

| 5 | Supports human detection functions such as image detection, synchronous snapshots, offline modification of measurement elements, and modification of custom element names | |

| 6 | Support 2D CAD theoretical elements for fast navigation measurement, measurement without reference contour, custom template export data | |

| 7 | Support output data to encrypted EXCEL, maximum value, direct calculation of minimum value, program translation copy function | |

| 8 | Industry-leading map navigation function, which doubles the programming and measurement speed, saving time and improving efficiency | |

| 9 | Support automatic compensation of line ruler, prompting of measurement abnormality, statistics function of EXCEL report chart | |

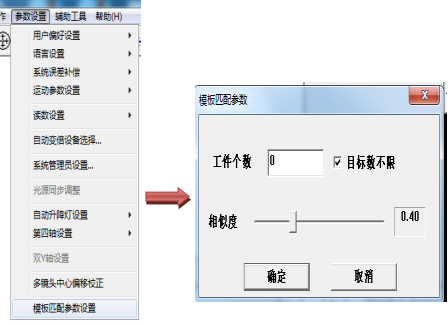

| Template matching similarity function | The software enables the template similarity matching function, and can modify the template similarity value when creating a template. The operation is as follows: parameter setting-template matching parameter setting; drag the similarity bar with the mouse to adjust the similarity (For one-button measurement) | |

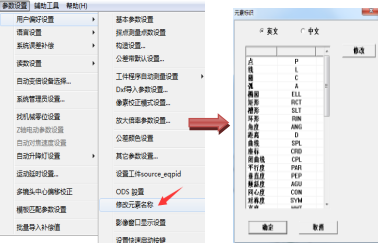

| Element name modification | 1. Element names can be modified; parameter settings-user preferences-modify element names. | |

| Modify image window size at will | Instrument software image window size can be modified; parameter settings-user preferences-image window display settings; | |

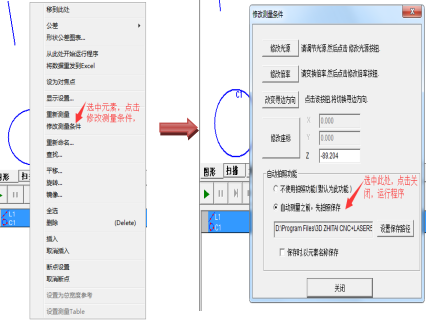

| Modifying measurement elements offline | Software can modify elements offline After the program finishes running, select an element for the element that has saved the picture, right-click in the element measurement method window and select Edit offline picture. You can modify the element of the currently saved picture without moving the workbench;  | |

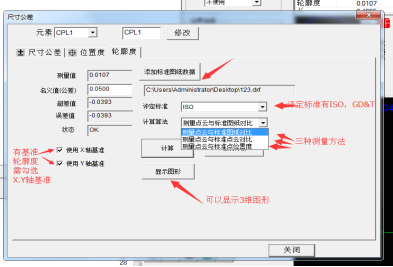

| Measurement without reference profile | 1. Contour measurement, which can measure with and without reference contour. There are two evaluation standards: ISO and GD. There are three methods for measuring with reference contour: 2. Comparison of measurement point cloud and standard drawing, comparison of measurement point cloud and standard point cloud, comparison of measurement point and standard point position  | |

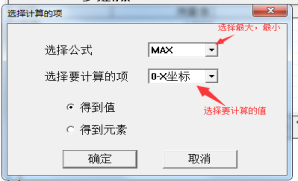

| Calculation function of the maximum and minimum values and the distance between multiple lines and circles |   | |

| Warpage calculation function | Warpage calculation function. After measuring the structural surface by stepping on the laser, there will be flatness and warpage. (It can be displayed in the element content.) You can set upper and lower tolerances for warpage. You can directly display the Z-value projection data of each point on the plane in the graphics window. The operation is as follows: parameter value-user preferences-other parameter settings-Tick the Z-value projection data of each point on the display plane, confirm the point, and click the left mouse button in the graphics window to display the Z value of each point Projection data. | |

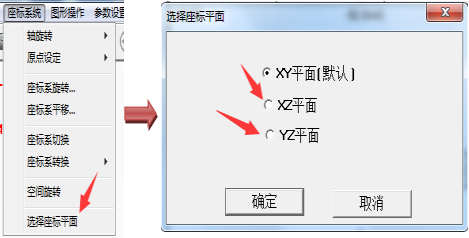

| Space rotation function | The software adds the selection function of the projection surface, the laser point can be reused to reduce the measurement time, and the coordinate values on different surfaces can be displayed. The operation is as follows: First use the laser to step on the point to measure. After the measurement is completed, you can choose the projection plane, coordinate system, and coordinate plane. The software defaults to the XY plane. You can manually select the XZ or YZ plane.  | |

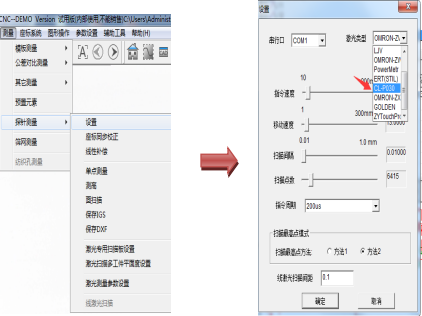

| Spectral confocal laser |  | |

| Reverse scan function | The software is upgraded on the basis of the original scanning. The scanned point cloud can directly construct points, arcs, circles, straight lines, etc. in the software. Click the software scan window to scan the graphic, and double-click the graphic in the scan window. | |

| Customized report settings | The software supports two report output methods. The new output method will be faster and easier to operate. | |

| 1 | The whole machine adopts an integrated design scheme and is equipped with a bottom roller, which comprehensively solves the transportation and placement of the instrument. The instrument desktop adopts a detachable design concept to fully realize the overall beauty and use of the instrument. The use of sheet metal materials has a long service life. | |

| 2 | This instrument adopts the latest anti-collision design, which comprehensively solves the collision between the working table during the use of the instrument or during the transportation, which better guarantees the accuracy of the instrument during transportation or moving and placing. | |

| 3 | The mobile device adopts Germany's advanced toothless nut transmission design, which comprehensively solves the problem of screw drive transmission wear and prolongs the service life of the instrument. | |

| 4 | This instrument uses Taiwan's high-precision H-class linear guides to ensure the stability and reliability of the instrument's mechanical accuracy. | |

| 5 | Adopt international standard electrical design and installation methods to better ensure the stability and safety of the instrument. All lines are clearly marked for easy maintenance | |

| 6 | The position of the zoom tube is continuously variable, and the magnification can be easily changed without re-calibrating the pixel accuracy. | |

| 7 | X, Y-axis precision cross roller guide Z-axis Taiwan "Shangyin" linear guide to ensure the accuracy and straightness | |

| 8 | Parallel light path transmission light source, accuracy of measurement block ≤0.002mm, accuracy of stylus gauge ≤0.003mm | |

| 9 | 0.001mm resolution scale, high accuracy, strong anti-interference, long life | |

| 10 | Marble base structure, high stability, low changeability, can be used up to 40-50 years | |